OSHA 10 HR Construction Course – FLUSHING May 16 & 23

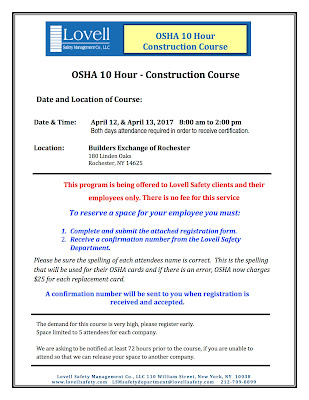

OSHA 10 Hour April 12 & April 13 in Rochester NY

To aid in your compliance with the various Federal, State and City regulations requiring this training, the LSM safety department is once again offering the OSHA 10 Hour Course. The course is provided by our OSHA certified instructors. Each employee who successfully completes the program will receive a certification card from OSHA.

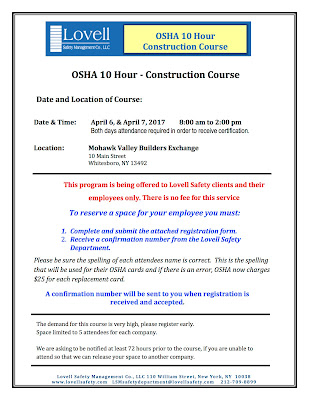

OSHA 10 Hour Course April 6 & April 7 In Whitesboro, NY

To aid in your compliance with the various Federal, State and City regulations requiring this training, the LSM safety department is once again offering the OSHA 10 Hour Course. The course is provided by our OSHA certified instructors. Each employee who successfully completes the program will receive a certification card from OSHA.

OSHA’s New Rules on Retaliation Incentive Programs, Post-Incident Drug Testing and Disciplinary Programs

need to determine whether or not their safety incentive programs, as well as their

post-accident drug and alcohol testing programs and disciplinary program,

comply with OSHA’s new requirements.

OSHA published a final rule that updated requirements for reporting

work-related injuries and illnesses, which also included a new provision that specifically

addressed retaliation for reporting incidents. Subsequently, OSHA released a

memo providing guidance on how to comply with the various requirements found in

the final rule. The memo addresses an employer’s obligation to have “reasonable

procedures” in place for employees to report injuries and illnesses without the

fear of retaliation.

anti-retaliation section, which is one of the most important for employers to

understand, describes what OSHA will consider a violation when looking at the

overall reporting program—especially in determining if there is a potential for

retaliation against employees who report incidents (for example, withholding a

benefit—such as a cash prize drawing or other substantial award—simply because

of a reported injury or illness). The

rule doesn’t prohibit incentive programs.

incentive programs that deter or discourage any employee from reporting an

injury or illness.

Safety Incentive Programs

promote worker participation in safety-related activities. Not only will these

types of incentive programs comply with OSHA, but they will also be more

effective in encouraging safe behavior, thereby reducing the number of injuries.

Some examples of behaviors that can be rewarded with an effective incentive

programs include:

- Participation

in safety program activities and evaluations; - Completion

of safety and health training; - Reporting

and responding to hazards and close calls/near misses; - Safety

walk-throughs and identification of potential safety hazards; - Compliance

with planned preventive maintenance schedules; - Following workplace

safety rules.

safety incentive program is to reward safe behavior rather than the lack of an

injury. A positive way of accomplishing this is by setting up a program that will

provide a cash prize for each work group that goes an entire month with all

members of the work group complying with specific safety rules, such as wearing

required fall protection. Supervisors of each work group should be rewarded as

well. Rewards should be at least every 6 weeks, and can build up to a year-long

grand prize.

such an incentive program, what happens if an employee sustains a lost-time

injury by falling off a platform while not wearing the required fall protection

and he reports the injury to the employer? The employer can then cancel the cash prize

drawing for that specific work group that month because the employee failed to

wear the required fall protection, NOT because he was injured. However, there

must be an active incentive program in place and the employer must be actively

monitoring for compliance. Employees cannot receive the reward when they do not

use the fall protection, regardless of whether or not an injury occurred.

testing required by the Department of Transportation rules or any other federal

or state law. It only

prohibits employers from using drug testing, or the threat of drug testing, to

retaliate against an employee for reporting an injury or illness.

Employers can

conduct post-incident drug testing if there is a “reasonable possibility” that employee drug use could have

contributed to the reported injury or illness. However, if employee drug use

could not have contributed to the injury or illness, post-incident drug testing

would likely only discourage reporting without contributing to the employer’s

understanding of why the injury occurred. Drug testing under these conditions

could be considered retaliation.

For example,

if an employee reports a repetitive strain injury and the employer requires

post-incident drug testing, then that testing would be prohibited because it is

unlikely that a repetitive strain injury would be related to drug use by the

employee. In a different situation, it would be reasonable for an employer to

require post-incident drug testing for a worker who reported an injury while

operating a forklift if the employee’s conduct contributed to the injury.

Employers do not need to specifically suspect drug use before post-incident

testing, but there should be a “reasonable”

possibility that drug use by the reporting employee could have contributed to

the reported injury or illness. Prior to any drug/alcohol testing a company

policy must be in place and administered uniformly.

action, or the threat of disciplinary action, to retaliate against an employee

for reporting an injury or illness.

employees simply because they report work-related injuries or illnesses without

regard to the circumstances of the injuries or illnesses, such as automatically

suspending workers who report an injury. The rule also does not allow disciplining

an employee who reports a work-related injury or illness by stating that

the employee violated a work rule if the real reason for the discipline was the

reporting of an injury. For example, if an employer disciplines an employee who

reported a work-related injury for violating a work rule, but fails to enforce

the work rule against other employees who violate the same rule but do not

report an injury. It is the same as described in the safety incentive program

criteria.

retaliation is seen is when an employer disciplines an employee who reported an

injury or illness for violating a vague rule such as “work carefully”

or “paying attention.” In this example, the reported injury or illness

is often the only basis for disciplining the employee. A rule of thumb to

follow is if the employee had not reported the injury or illness, would the

employer have still disciplined the employee?

If not, then the employer cannot discipline them if they report an

injury.

Effective and legitimate

workplace safety programs should treat all workers who violate safety rules in

an equivalent manner, regardless of whether or not the violation resulted in

the worker reporting an injury or illness. On the other hand, employees who

follow the rules should be rewarded fairly and equally as well.

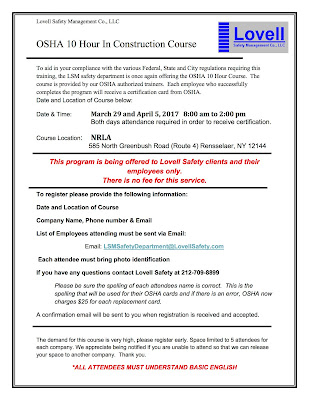

OSHA 10 Hour Construction Course March 29 and April 5, 2017 Rensselaer NY

To aid in your compliance with the various Federal, State and City regulations requiring this training, the LSM safety department is once again offering the OSHA 10 Hour Course. The course is provided by our OSHA certified instructors. Each employee who successfully completes the program will receive a certification card from OSHA.

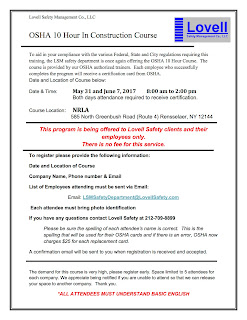

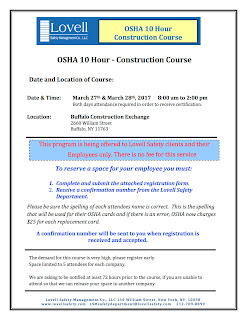

OSHA 10 Hour Construction Course March 27 and 28, 2017

To aid in your compliance with the various Federal, State and City regulations requiring this training, the LSM safety department is once again offering the OSHA 10 Hour Course. The course is provided by our OSHA certified instructors. Each employee who successfully completes the program will receive a certification card from OSHA.

Winter Weather Be Prepared

- Employers Should:

- Dressing Properly for the Cold

- Safety Tips for Workers

Employers Should Train Workers

- Cold Stress:

- How to recognize the symptoms of cold stress, prevent cold stress injuries and illnesses

- The importance of self-monitoring and monitoring coworkers for symptoms

- First aid and how to call for additional medical assistance in an emergency

- How to select proper clothing for cold, wet, and windy conditions

- Other winter weather related hazards that workers may be exposed to, for example, slippery roads and surfaces, windy conditions, and downed power lines

- How to recognize these hazards

- How workers will be protected: engineering controls, safe work practices and proper selection of equipment, including personal protective equipment

Employers Should Provide Engineering Controls

Employers Should Implement Safe Work Practices

- Providing workers with the proper tools and equipment to do their jobs

- Developing work plans that identify potential hazards and the safety measures that will be used to protect workers

- Scheduling maintenance and repair jobs for warmer months

- Scheduling jobs that expose workers to the cold weather in the warmer part of the day

- Avoiding exposure to extremely cold temperatures when possible

- Limiting the amount of time spent outdoors on extremely cold days

- Using relief workers to assign extra workers for long, demanding jobs

- Providing warm areas for use during break periods

- Providing warm liquids (no alcohol) to workers

- Monitoring workers who are at risk of cold stress

- Monitoring the weather conditions during a winter storm, having a reliable means of communicating with workers and being able to stop work or evacuate when necessary

- Acclimatizing new workers and those returning after time away from work by gradually increasing their workload, and allowing more frequent breaks in warm areas, as they build up a tolerance for working in the cold environment

- Having a means of communicating with workers, especially in remote areas

- Knowing how the community warns the public about severe weather: outdoor sirens, radio, and television

- The National Oceanic and Atmospheric Administration (NOAA) provides multiple ways to stay informed about winter storms. If you are notified of a winter storm watch, advisory or warning, follow instructions from your local authorities: NOAA Weather Radio

Employers Should Consider Protective Clothing that Provides Warmth

Dressing Properly for the Cold

- Wear at least three layers of loose fitting clothing. Layering provides better insulation.

- An inner layer of wool, silk or synthetic (polypropylene) to keep moisture away from the body. Thermal wear, wool, silk or polypropylene, inner layers of clothing that will hold more body heat than cotton.

- A middle layer of wool or synthetic to provide insulation even when wet.

- An outer wind and rain protection layer that allows some ventilation to prevent overheating.

- Tight clothing reduces blood circulation. Warm blood needs to be circulated to the extremities. Insulated coat/jacket (water resistant if necessary)

- Knit mask to cover face and mouth (if needed)

- Hat that will cover your ears as well. A hat will help keep your whole body warmer. Hats reduce the amount of body heat that escapes from your head.

- Insulated gloves (water resistant if necessary), to protect the hands

- Insulated and waterproof boots to protect the feet

Safety Tips for Workers

- Your employer should ensure that you know the symptoms of cold stress

- Monitor your physical condition and that of your coworkers

- Dress appropriately for the cold

- Stay dry in the cold because moisture or dampness, e.g. from sweating, can increase the rate of heat loss from the body

- Keep extra clothing (including underwear) handy in case you get wet and need to change

- Drink warm sweetened fluids (no alcohol)

- Use proper engineering controls, safe work practices, and personal protective equipment (PPE) provided by your employer

OSHA 10 Hour Construction Course Flushing, NY

Heat Illness Can Be Deadly.

Employers must protect workers from excessive heat.

- Provide workers with water, rest and shade.

- Allow new or returning workers to gradually increase workloads and take more frequent breaks as they acclimatize, or build a tolerance for working in the heat.

- Plan for emergencies and train workers on prevention.

- Monitor workers for signs of illness.

To prevent heat related illness and fatalities:

- Drink water every 15 minutes, even if you are not thirsty.

- Rest in the shade to cool down.

- Wear a hat and light-colored clothing.

- Learn the signs of heat illness and what to do in an emergency.

- Keep an eye on fellow workers.

- “Easy does it” on your first days of work in the heat. You need to get used to it.

Who is affected?

What to do if a worker becomes ill?

- Call a supervisor for help. If a supervisor is not available, call 911.

- Have someone stay with the worker until help arrives.